Streamline Your Operations with High-Performance Conveyor Systems

Boost efficiency and productivity with a robust conveyor system from Swisser Instruments Pvt Ltd, a leading manufacturer and supplier known for their reliable and innovative solutions. Whether you’re in manufacturing, packaging, distribution, or any other industry, our conveyor systems provide seamless material handling to optimize your workflow.

Built by top Conveyor System Manufacturers in India, they offer a cost-effective and efficient means of transporting items and streamlining material handling within a facility without the need for manual intervention. Capable of moving thousands of items per hour, these systems, when deployed in parallel, can achieve virtually limitless handling capacities.

Built by top Conveyor System Manufacturers in India, they offer a cost-effective and efficient means of transporting items and streamlining material handling within a facility without the need for manual intervention. Capable of moving thousands of items per hour, these systems, when deployed in parallel, can achieve virtually limitless handling capacities.

Applications

Mines and other heavy utility

Warehouse and packaging line

Loading / unloading

Your Trusted Source of High-Quality Conveyor System

Conveyor systems have the versatility to accommodate a wide array of items and are utilized across various warehouse functions. Benefit from our extensive expertise and proven track record in conveyor technology.

As leading Conveyor System Suppliers in India, we use only the best materials and components to ensure long-lasting performance. Our team is here to help you choose the right system, provide installation support, and offer ongoing maintenance services.

Ready to streamline your operations and elevate your productivity? Contact Swisser Instruments today to discuss your conveyor system needs and discover how we can help you achieve your goals.

As leading Conveyor System Suppliers in India, we use only the best materials and components to ensure long-lasting performance. Our team is here to help you choose the right system, provide installation support, and offer ongoing maintenance services.

Ready to streamline your operations and elevate your productivity? Contact Swisser Instruments today to discuss your conveyor system needs and discover how we can help you achieve your goals.

Features

Decreased friction

Significant in airport baggage handling

Long service life

Rouged structure for suitable performance

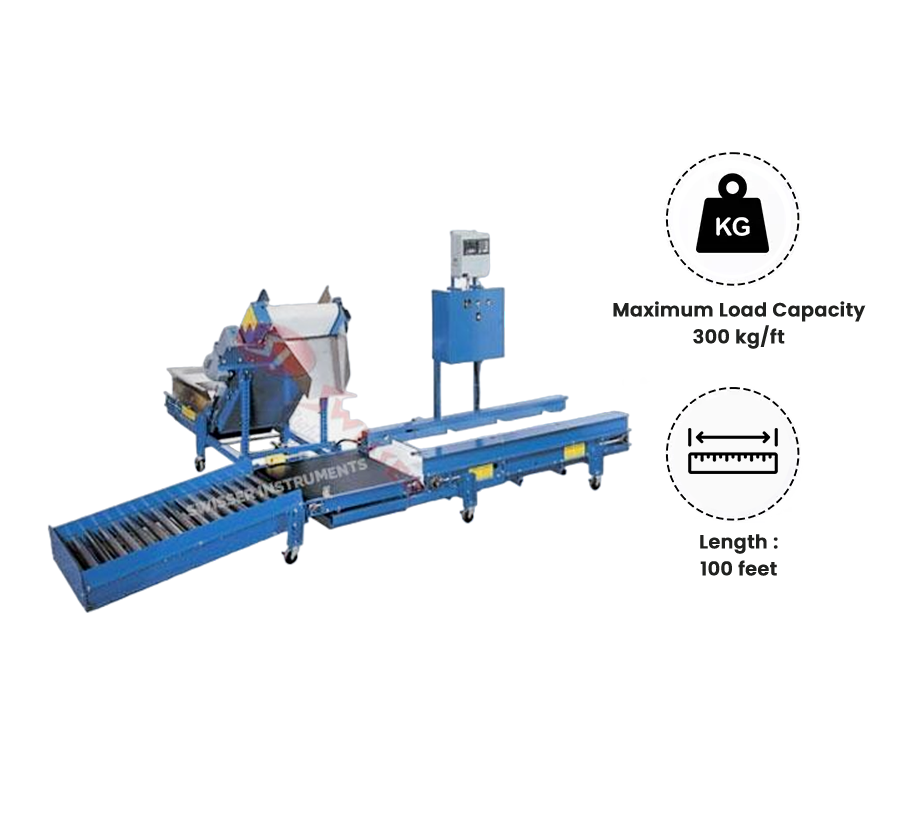

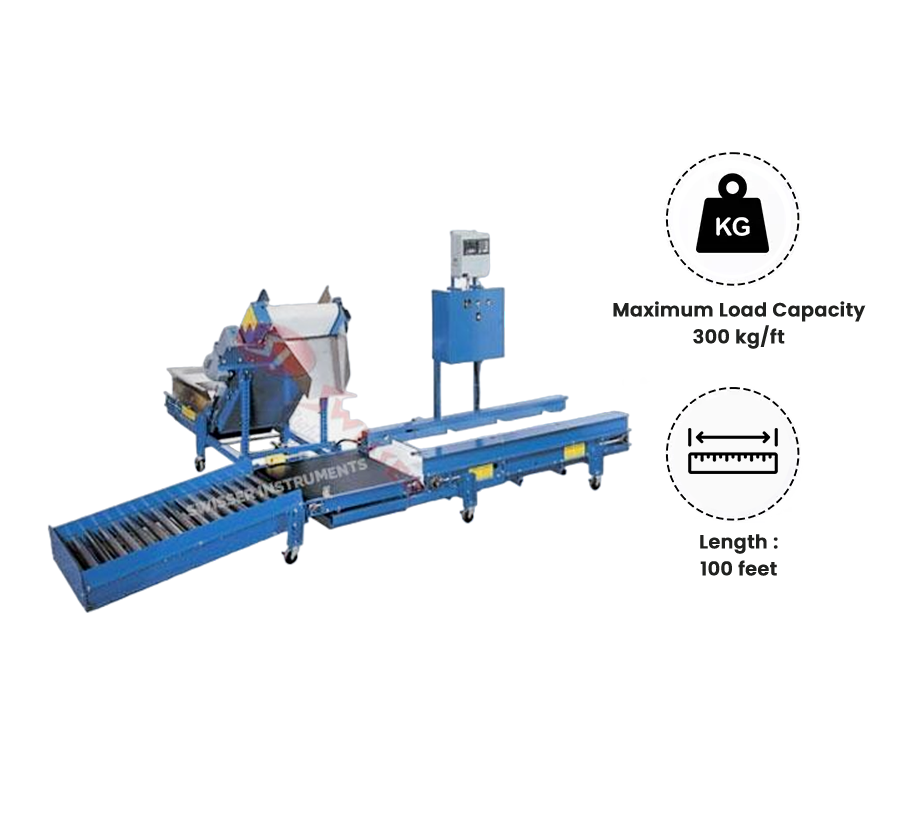

Specifications

Material: Aluminum, stainless steel

Material handling capacity: 1 to 50 kg/ft to 200 to 300 kg/ft

Length : 1 to 10 feet – 60 to 100 feet

Power : 230 V single phase + neutral

Conveyer size : 2 meter x 12 inch x 3.5 feet

Conveyor System

The SIPL Conveyor System can be easily fitted on any stringer conveyor by using one of the existing idler stations. It has particularly designed for bulk weighing, flow measurement and day production totaling during extraction, processing, prestorage phases, etc.

This product is adapted to all activity sectors using belt conveyors:

extraction industry (minerals, aggregates, coal…)

mineral industry (phosphate, fertilizers, cement…)

agri-business (cereals, bagasse, sugar…)

chemical industry (salts, PVC, washing powders…)

wood industry,– bio-mass,– recycling,– crushing

The Conveyor System scale is made up of oven-painted steel with RAL5012 thermo-hardening powder paint granting perfect protection against environmental induced aggressions. It is also available in 304L or 316L stainless steel version.

The SIPL Conveyor System is mainly made up of:– 2 load cell blocks designed for continuous weighing each fitted with an IP68 stainless steel strain gauge load cell.

These blocks include shock absorbers in case of large particle sizes and an overload mechanical stop, as well as a cunning idler station alignment device.

These blocks include shock absorbers in case of large particle sizes and an overload mechanical stop, as well as a cunning idler station alignment device.

2 section-adapted metal cross-bars (2) to connect the load cell blocks to the conveyor.

2 fastening spikes (3) to fasten the various types of idler station onto the scale.